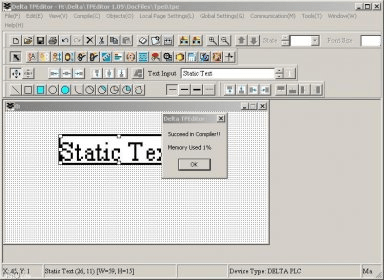

Fanuc Tp Editor Software

суббота 24 ноября admin 62

FANUC’s TP programming language and the teach pendant’s built-in editor are great tools. They allow relatively novice programmers to get up and running very quickly. Teach a couple points, throw in a couple labels and IF statements, and you’re off to the races. However, anyone who’s tried to do anything a bit more complex quickly realizes how cumbersome programming on the teach pendant is. Navigating through multiple levels of menus to find the PAYLOAD instruction or creating an extensive mixed-logic conditional is really painful.

E173Eu-1 and E153Eu-1 Kyivstar, Beeline, Viettel, Mobinil, Etisalat, XL indonesia and etc. Kod razblokirovki dlya mts modema zte mf 192 1.

Tp editor software download social advice Users interested in Tp editor software download generally download. Go launcher ex download for nokia x. FANUC America Corporation is the undeniable leader in robotics, CNC systems and factory automation solutions in the Americas.

At this point many programmers switch to programming.LS files by hand. Here’s the smallest program you can load onto a robot: /PROG A /ATTR However, it might be good practice to start with a template that includes all available sections: /PROG A /ATTR /MN /POS /END The /PROG section simply accepts the name of your program (letters, numbers and underscores only, and it must start with a letter) followed by an optional sub-type (e.g.

Macro, Cond, etc.). The /ATTR section stores the rest of the program header information: things like the creation date, comment, group mask, etc. If you choose not to include any of this, the robot assumes a sensible set of defaults. I’m not sure what /MN stands for (motion?), but this is where your program goes.

You must start each line with a: and end it with a. You can optionally include a line number before the colon, but I think including line numbers in your source code is a tragedy. /PROG A /ATTR /MN:! This is a comment; 2:! Don't do this.

Fanuc-TeachPendant Basics Table of Contents • • • • • • • • • • • • • • • • • • About Industrial Robots are difficult to control, they are made for specially trained personal and hardly accessible to anybody else. For our semester project at the we used a. This tutorial will show teach you the basics of the TeachPendant – a remote control by Fanuc to program their robots. Limitations Originally we planned to control the robot externally via tools such as. We were however not able to do that. If you have a solution to externally control the robot, feel free to fork this repo and add it to it.

Your help would be hugely appreciated. Controlling the Robot Unlocking the robot In order to control the robot you have to diactivate his safety mechanism – the: • Press and hold SHIFT • Press (half-way through) and hold one vertical yellow button on the rear of the TeachPendant • Keep holding these buttons (otherwise robot will go back into a locked mode) Set speed After power up, the robot's speed will be slow by default. Current speed is shown as percentage with a green background in the top right corner. You can control the maximum speed on the TeachPendant: • +% Raises speed • -% Lowers speed Note: The robot's speed in manual mode is only a fraction of what it will in automatic mode. Moving the robot There are multiple ways to control the robot. However, we only used the movement types 'JOINT' and 'WORLD'. They can be cycled through by pressing COORD on the TeachPendant.

The current mode will be shown in the top right with a black background. These settings affect the functions of the blue buttons (on the right of the TeachPendant) which control the robots movement: Joint The movement type 'JOINT' controls every joint individually. J1 = base joint: • +X(J1) Rotate anti-clockwise • -X(J1) Rotate clockwise J2 = lower arm joint: • +Y(J2) Rotates upwards • -Y(J2) Rotates downwards J3 = upper arm joint: • +Z(J3) Rotates upwards • -Z(J3) Rotates downwards J4 = 'hand' joint: • +X(J4) Rotates upwards • -X(J4) Rotates downwards J5 = tool mount joint: • +Y(J5) Rotates clockwise • -Y(J5) Rotates anit-clockwise J6 is not assigned in our robot (because it is only euqipped with five axis). Normally it would control the arm's rotation itself. World The movement type 'WORLD' defines one point, where the robot points to. This point is the tip of the tool mount. This means, that you just set where the tool mount's tip should be located and the robot will move all necessary joints to reach that position.